Industrial valves are used for regulating the flow of fluids, gases, and slurries in several sectors such as oil and gas, water, and wastewater treatment, and chemical industries. The production of these valves is not a simple process, and it involves a lot of detail in order to produce valves that can withstand harsh industrial conditions. This article gives a detailed insight into how industrial valves, especially those made by ball valves manufacturers are made. We will also be able to compare the process with that used by triple offset butterfly valves manufacturers.

Material Selection and Casting

The first process in manufacturing industrial valves is choosing the right material to be used in the manufacturing process. The selection of the material is very important because it determines the performance, reliability, and ability of the valve to withstand corrosion and high or low temperatures. Some of the materials that are used are stainless steel, carbon steel, brass, bronze, and other alloys. The material of ball valves is chosen depending on the application conditions, such as pressure, temperature, and the type of medium to be regulated.

After the material has been chosen, the casting process starts. In this stage, the raw material is melted and then cast into the required shape of the valve body and other parts. The casting process is also important because it determines the strength of the valve. After casting, the components are cooled and taken out of the molds, as shown in the figure below. They are then exposed to different heat treatments in order to improve their mechanical characteristics, including strength and hardness. The casting process that is used by the manufacturers of triple offset butterfly valves is similar to the one described above, but the details and the level of difficulty may vary depending on the type of valve that is being manufactured.

Machining and Precision Engineering

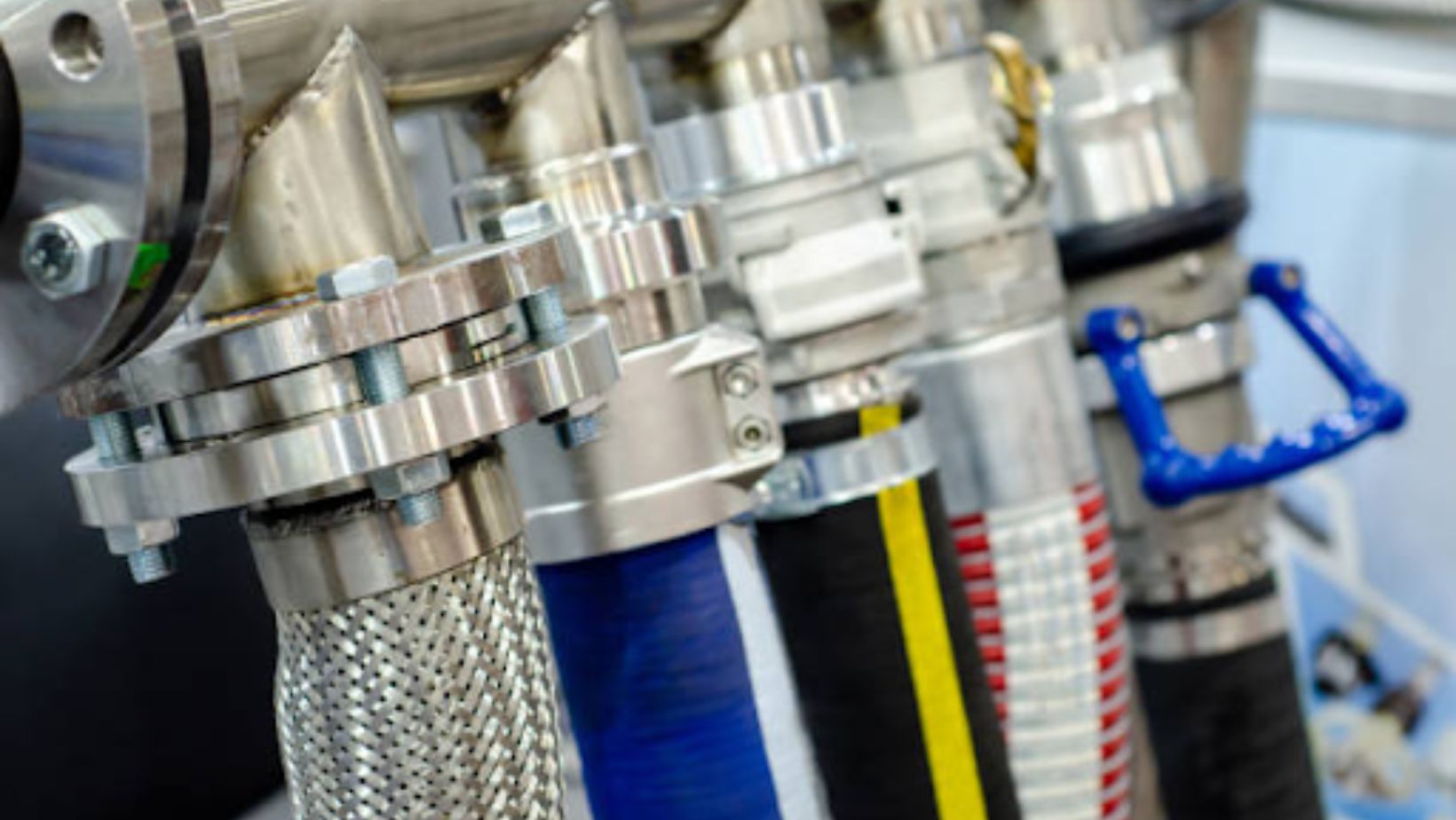

Following the casting process, the components of the valve are subjected to a machining process in order to get the right dimensions and a smooth surface. The cast parts are then machined through cutting, drilling, and shaping through CNC machines. These machines are able to create parts with high precision, which is very important in the valve’s working.

As for ball valves, the machining process involves the formation of the spherical ball, which controls the flow of the fluid. This ball must be perfectly round and smooth so that when the valve is closed, it will have a tight fit. The valve body, stem, and seats are also precision machined so that they will fit into each other tightly. Triple offset butterfly valve manufacturers also use precision machining in the production of the intricate disc and seat structure that enables the special sealing system of these valves. The level of accuracy in this stage is very important because any slight variation will lead to leakage or failure of the final product.

Assembly and Testing

After all the parts have been machined, the assembly process starts. In assembly, the various components are then assembled to form the complete valve. In the case of ball valves manufacturers, this process entails placing the ball in the valve body and fastening it with the stem and seats. The valve is then fitted with other parts including gaskets, seals and fasteners to make sure that the valve does not leak.

After the assembly of the valves, they are tested to meet the required standards and specifications in the market. Some of the tests that are usually conducted include pressure tests, leak tests, and functional tests. Another type of test is the pressure test, where the valve is exposed to high pressure to determine if it will be able to handle the working conditions without bursting. Leak testing confirms that no fluid is leaking through the seals, and functional testing confirms that the valve is working as it should. Manufacturers of triple-offset butterfly valves also conduct similar tests, with extra emphasis on the sealing capability of the triple-offset feature of the valve.

Surface Finishing and Coating

In order to improve the service life and the resistance to corrosion of the valves, they are subjected to surface treatment and coating. The process of surface finishing is to smoothen the outer surface of the valve by polishing or grinding the surface to make it free from any defects. This step is especially important for valves that are to be used in applications where cleanliness is paramount for example in the food and beverage industry.

Coating is another important process in the product manufacturing process. Valves are usually painted or given some kind of epoxy, PTFE (Teflon), or any other suitable coating to avoid corrosion, wear, or chemical attack. The type of coating to be applied on the valve depends on the use that is to be put on the valve. Ball valve manufacturers normally use coatings that are appropriate to the conditions that the ball valves will be exposed to. Likewise, when it comes to the selection of coatings for triple offset butterfly valves, manufacturers choose those that will improve the performance and durability of the valve in unfavorable environments.

Quality Control and Final Inspection

The last process in the manufacturing process is quality assurance and checking. The valves are tested and checked before they are sold to customers to ensure that they are of high quality and standard. This inspection entails a visual inspection for defects, a dimensional inspection, and a check on the test results from previous phases.

Quality assurance is a very important factor in the production of ball valves since the valves are used in industries such as oil and gas, chemical processing, and water treatment. Triple offset butterfly valve manufacturers also pay much attention to the quality of their products because their valves are used in severe service.

In conclusion, the manufacturing of industrial valves is a complex process that includes material selection, casting, machining, assembling, testing, and quality control. Manufacturing processes of ball valves and triple offset butterfly valves are almost the same, with slight differences depending on the type of the valve. Thus, these companies strictly follow these manufacturing standards to guarantee their valves’ performance in the harshest conditions of the industry.