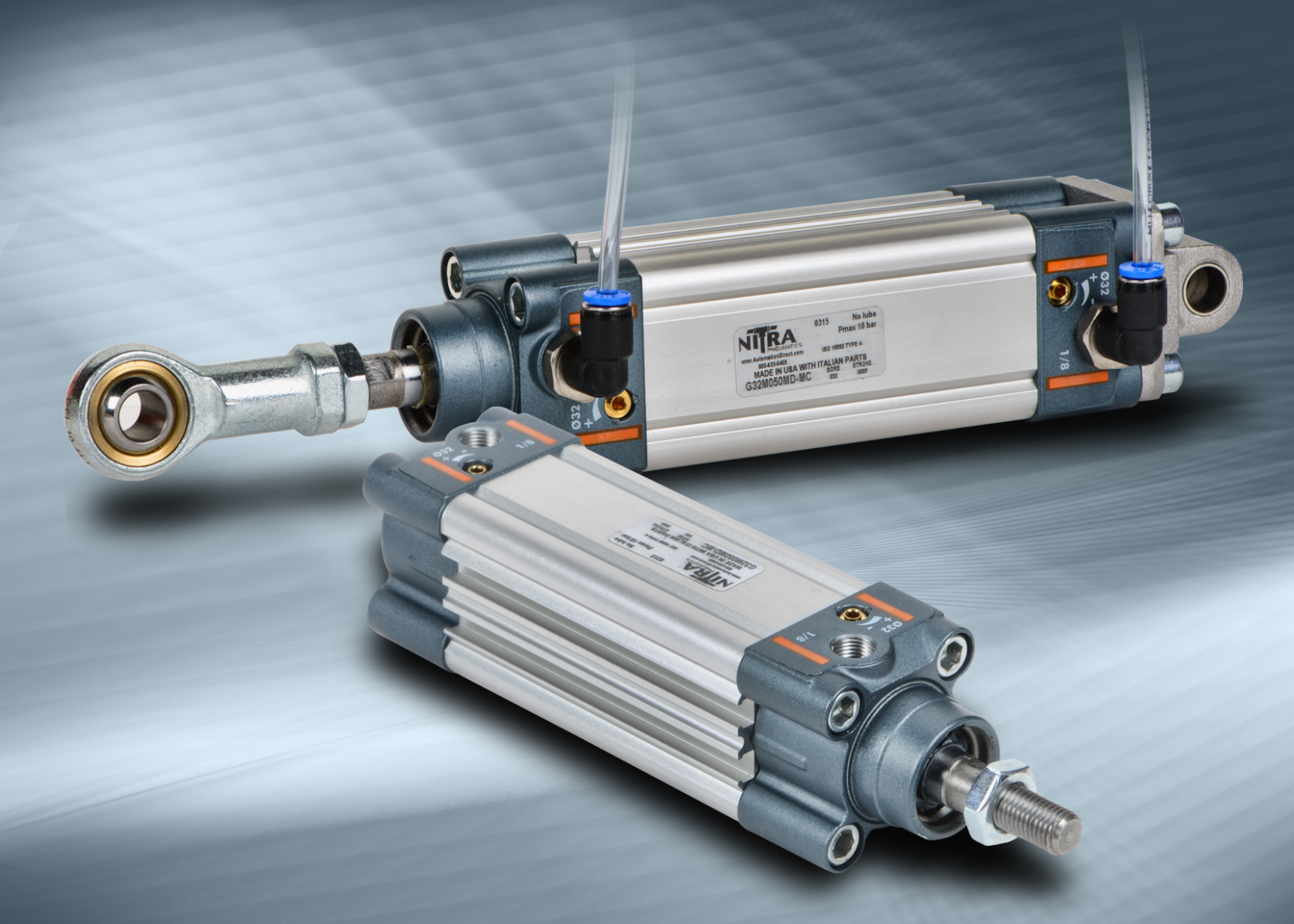

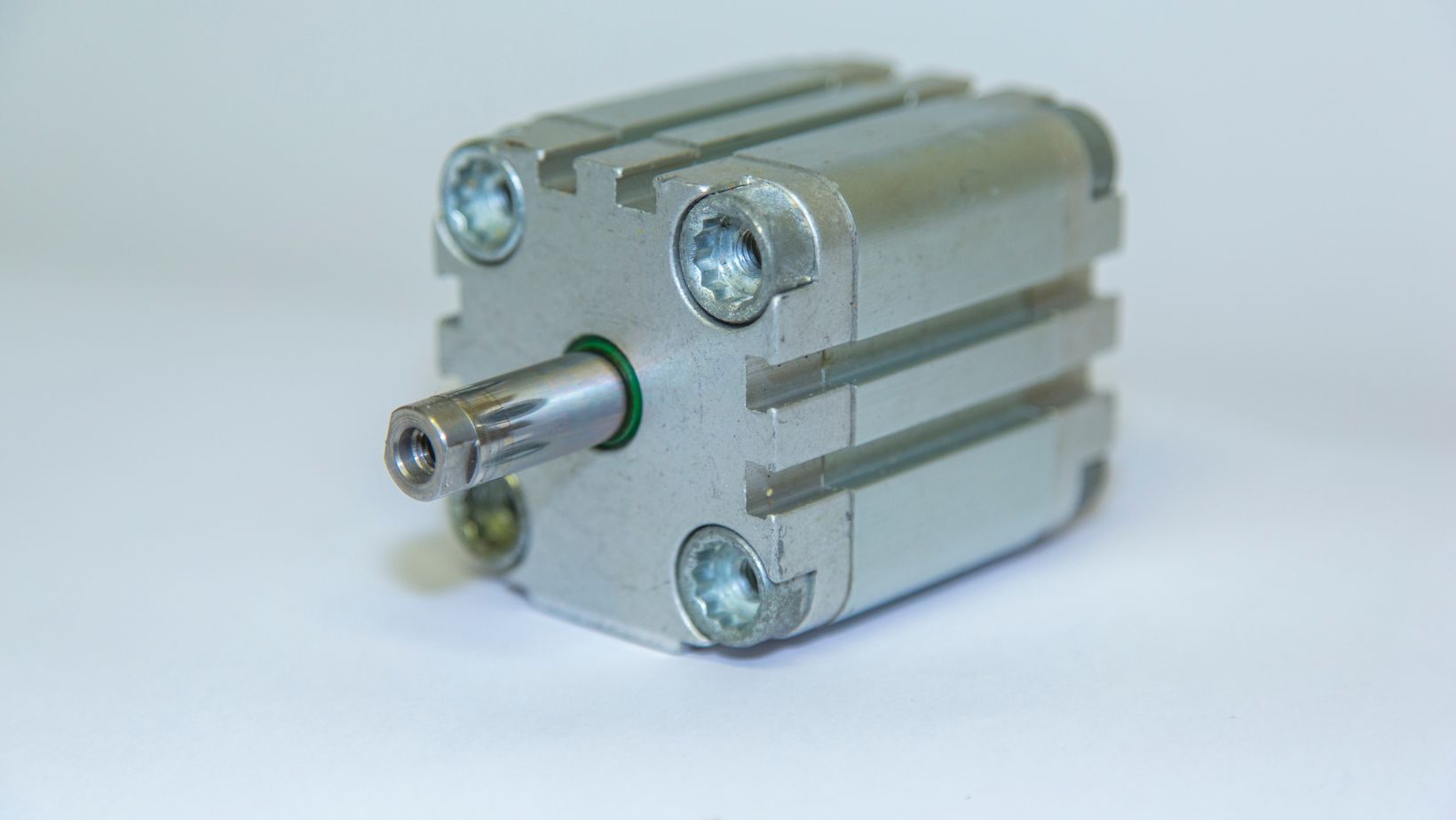

Pneumatic cylinders are standard products in industrial automation systems as they serve as the motion control in many processes. These devices are invaluable in many industries because of their flexibility, durability, and low price. When business organizations continue to search for ways in which production processes could be improved, knowledge of the use of pneumatic cylinders would be helpful. In this article, the author will discuss the practical uses of pneumatic cylinders in different fields and demonstrate the significance of these components in increasing performance. The details presented herein are especially useful for B2B companies, such as those related to the finest industrial automation companies and pneumatic cylinder distributors.

Manufacturing and Assembly

Pneumatic cylinders are used frequently in the manufacturing and assembly industry because of their capacity to deliver force in linear motion which is accurate, reliable, and consistent. In automobile manufacturing for example, the applications of pneumatic cylinders is in the actuation of assembly lines where they are used for the positioning, clamping and movement of parts. This assists in avoiding mistakes and at the same time increasing the rate of production which is important in mass production.

Pneumatic cylinders are also used in the packaging lines where they work on operating the machinery involved in sealing, cutting, and labeling among others. These cylinders make sure that each operation carried out is standard, thus minimizing mistakes and maximizing flow. Manufacturers who incorporate pneumatic cylinders into their processes will be able to experience major gains in productivity and quality.

Food and Beverage Industry

In the food and beverage industry, the impact of Pneumatic cylinders cannot be overemphasized as they help to provide hygienically and safe production with high production rates. This is especially important in industries that require minimal contamination of their working environment and thus, pneumatic systems are the best. Pneumatic cylinders are in the application of packaging, filling and sealing equipment to ensure gentility in handling the products.

For instance, in the beverage bottling industries, the pneumatic cylinders regulate the flow valves where the correct amount of the beverage is filled into the bottle. They also use capping machines that place lids at high speed while at the same time do not harm the containers. In these applications, pneumatic cylinders are very reliable hence they do not cause production downtimes frequently.

In addition, pneumatic cylinders are applied in sorting and handling systems for product transportation on conveyors and for segregation of various types of products. It is important when it comes to satisfying the production requirements in the food and beverage industry.

Material Handling and Logistics

The material handling and logistics industry widely uses pneumatic cylinders for different automation purposes. From palletizing to sorting and stacking, pneumatic cylinders are used to transport and reposition goods and products in warehouses and distribution centers. Because of this feature, they are suitable for moving and controlling force and motion of various sizes and weights of goods.

In AS/RS, the pneumatic cylinders are employed to operate the robotic arms and grippers to pick up objects and place them in the right location. This automation reduces the amount of manual work, shortens the time taken in processing orders, and increases the general productivity of logistics systems.

Pneumatic cylinders are also used in conveyor systems as they assist in the regulation of flow of products by controlling gates, stops and diverters. This level of control is important to make sure that the flow of goods through various stages of the supply chain is efficient.

Pharmaceuticals and Medical Devices

Pharmaceutical and medical devices are one of the industries that need high accuracy, dependable, and hygiene manufacturing processes. Pneumatic cylinders are very appropriate for these surroundings since they provide adequate control for manipulating sensitive products and subassemblies without compromising their integrity.

In pharmaceutical production, applications of pneumatic cylinders can be used in equipment for pressing the tablets, filling capsules and packaging. This way their operators can control the dosing and the filling of the medications to the perfection and the product meets all the legal requirements. Pneumatic cylinders also work in cleanrooms to control automation systems that move products in the area.

In the medical device industry, pneumatic cylinders are used in the construction of product subassemblies which includes syringes, catheters and diagnostic equipment. These cylinders offer the force and control required in assembling parts that are closely tolerant to guarantee that each of the devices is made to standard.

Energy and Power Generation

Another application area is the energy and power generation industry where pneumatic cylinders are employed in numerous control and automation processes. In power plants, the pneumatic cylinders are used to control the valve that controls the flow of steam, water and other fluids that are required for generation of power. These cylinders have to function in extreme conditions such as high pressure and temperature.

In the oil and gas industry, pneumatic cylinders are applied in drilling rigs and pipelines for controlling the motion of equipment and the flow of oil and gas respectively. This makes them suitable for the aforementioned applications since they are capable of operating under unfavorable conditions.

Also, pneumatic cylinders are applied in renewable power systems like wind power systems where they are involved in controlling the brake system and positioning of the blades for energy harnessing. In these systems, their contribution is vital in ensuring the effectiveness and safety of renewable energy systems.

Pneumatic cylinders are used in a number of applications in industries to provide accurate, fast and cheap motion control solutions. These cylinders are used in almost all fields of industries, right from manufacturing and assembly industries to energy and power industries, to improve the efficiency of the automatic systems. Therefore, to B2B businesses that deal with industrial automation, the various uses of pneumatic cylinders will enable them to choose the right solution for their operations.

Thus, cooperating with the leaders in the industrial automation industry while working with a reliable pneumatic cylinder supplier, businesses can be sure that they will use only the best parts for automation. Thus, the pneumatic cylinders remain a significant technology in the further development of the food and beverage industry, material handling, and pharmaceutical industries.