When I first heard about Bambu Lab’s TPU filament, I was intrigued by its promise of flexibility and durability. As someone who’s dabbled in 3D printing, I know how crucial it is to choose the right filament for the job. TPU, or Thermoplastic Polyurethane, stands out for its unique properties, making it a favorite among hobbyists and professionals.

What is TPU Filament?

TPU filament, or Thermoplastic Polyurethane, is a popular 3D printing material known for its flexibility, chemical resistance, and elasticity. Ideal for creating soft objects, it offers a unique balance of durability and flexibility, making it perfect for items like phone cases and stress-relief toys. TPU’s chemical resistance allows it to withstand exposure to various solvents, enhancing its versatility in diverse applications. Additionally, its elasticity means that it can return to its original shape even after being deformed, making it a resilient choice for functional and flexible prints.

Types of Bambu Lab TPU Filaments

Bambu Lab offers TPU filaments with varying characteristics, catering to different printing needs.

Bambu TPU 95A HF and Its Characteristics

Bambu TPU 95A HF is a standout filament noted for its shore hardness of 95A. It’s known for the perfect balance of strength and flexibility, making it suitable for functional and flexible parts.

Benefits of Using Bambu Lab TPU Filament

Using Bambu Lab TPU filament has a mix of benefits that make 3D printing efficient and versatile. Let me explain.

Flexibility and Elasticity

Bambu Lab’s TPU filament offers flexibility and elasticity, which makes it great for parts that require bending without breaking. I once printed a set of protective gaskets with this filament; they fit snugly, adapting to variations in surface shapes while retaining their form. This ability to stretch and return to its shape is essential for projects involving fittings and seals.

Impact Resistance

This filament stands out for its impact resistance. It’s perfect for items needing to withstand drops or bumps. I made a rugged phone cover using Bambu Lab TPU filament that survived several accidental falls without a scratch. The filament absorbs the shock, keeping parts intact and functional, which is reassuring for durable product designs.

High-Speed Printing Capabilities

Printing with Bambu Lab TPU filament doesn’t mean sacrificing speed. Thanks to its excellent flow characteristics, it allows high-speed printing. Faster print speeds don’t jeopardize the finish quality; I rapidly completed a batch of flexible hinges without losing any detail. It’s a timesaver when producing multiple iterations or meeting tight deadlines.

Recommended Printing Settings for Bambu Lab TPU 95A HF

Dialing in the right settings for Bambu Lab TPU 95A HF brings flexibility and strength to printed items. It’s satisfying when each print turns out just like it’s supposed to.

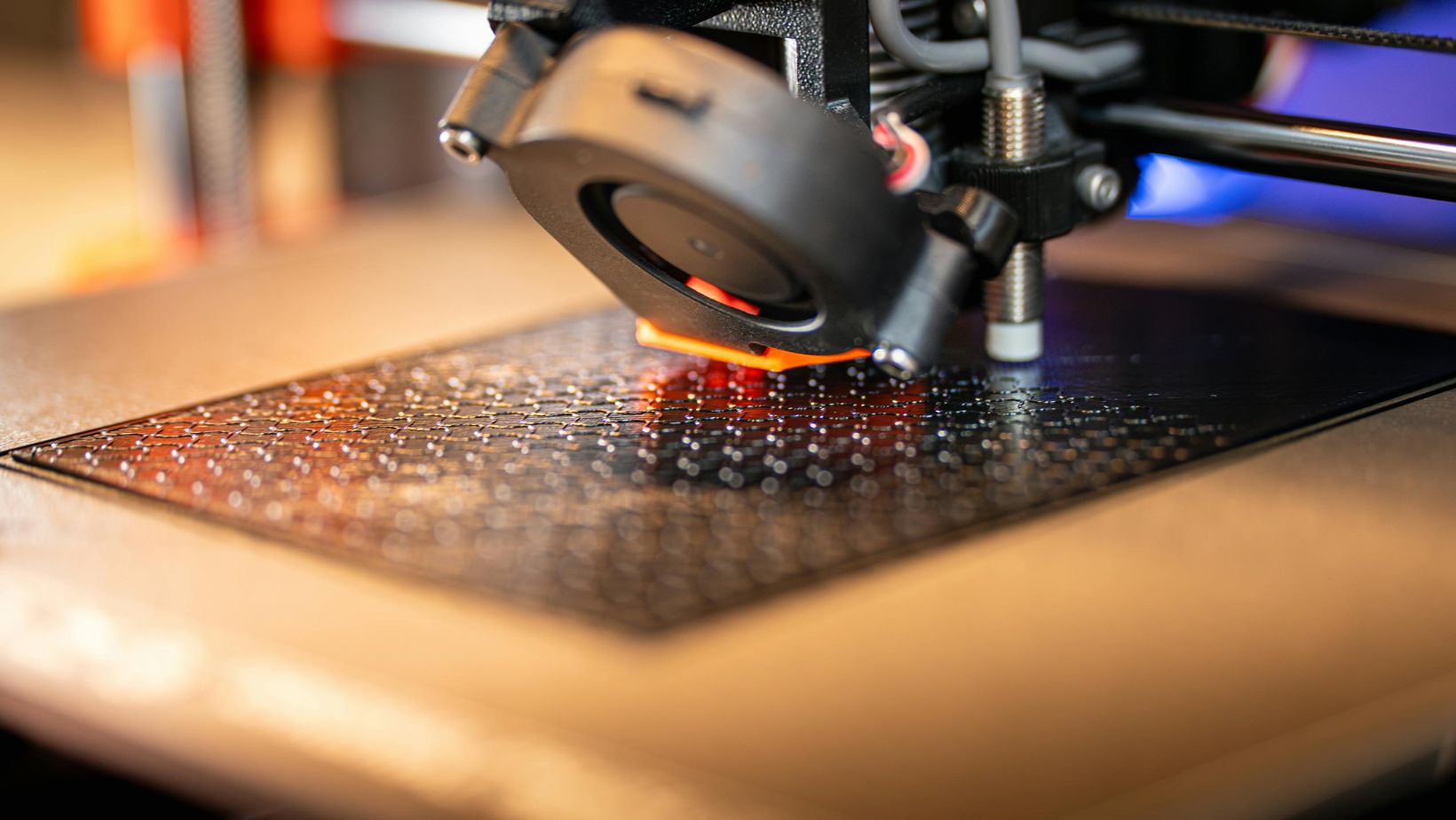

General Guidelines

Before starting, set the nozzle temperature to 225°C. Keep the print bed around 50°C for best adhesion. Adjust retraction to 1 mm at 25 mm/s to avoid stringing. I’ve learned these settings lead to fewer errors and smoother surfaces for TPU filament prints.

Drying Recommendations

TPU loves to soak up moisture, which hinders print quality. Store it in a dry box or use a filament dryer at 55°C for 4 hours before printing. My old prints were a mess before taking drying seriously—small adjustment, big payoff.

Speed and Flow Rate Settings

The print speed should hover around 30 mm/s. To compensate for the filament’s flexibility, set the flow rate to 105%. These settings help maintain consistency, allowing even tricky designs to print flawlessly.

Applications of Bambu Lab TPU Filament

Industrial Uses

TPU filament excels in industrial applications due to its durability and flexibility. Companies in automotive manufacturing often use it for custom-fit gaskets and seals, a necessity for parts that endure stress without losing shape. In my experience, this filament’s ability to withstand harsh conditions made it an excellent choice for printing protective covers for machinery components. Medical device makers also benefit from its benefits—it’s perfect for soft, wearable parts like braces and grips due to its biocompatibility and comfort.

Creative Projects

Creativity thrives with TPU filament’s flexible properties. In fashion design, artists appreciate its elasticity for wearable art, including intricate accessories and fittings.

Conclusion

Embracing Bambu Lab TPU filament has transformed my 3D printing projects. Once, while crafting a custom phone case, I discovered its remarkable elasticity and durability. It withstood numerous drops, proving that TPU filament is the go-to choice for stress-resistant, flexible creations. Whether you’re into industrial or creative ventures, TPU filament is a versatile option that delivers consistent results.